We provide our customers with all the technical information to support the project, including structural checks and assembly specifications. Furthermore, it is possible to evaluate solutions specifically designed to cope with particular design specifications.

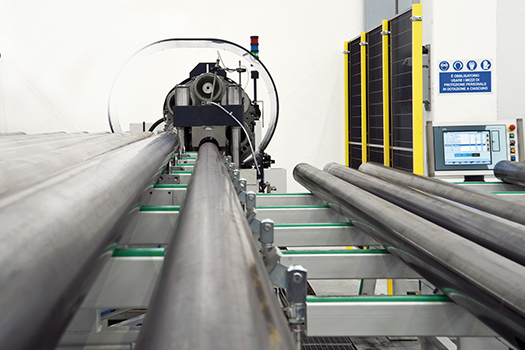

The cutting operations are performed with laser source machinery capable of guaranteeing maximum precision in cuts, holes and slots and any other processing required by the project of the particular pole.

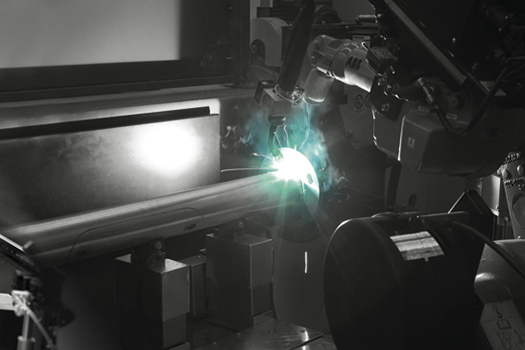

A robotic island is dedicated to the welding of the tubes in the various sections. The process is carefully controlled by qualified personnel according to the provisions of ISO 14732 and ISO 9606-1 standards and carried out in compliance with ISO 15609-1 and ISO 15614-1 safety standards.

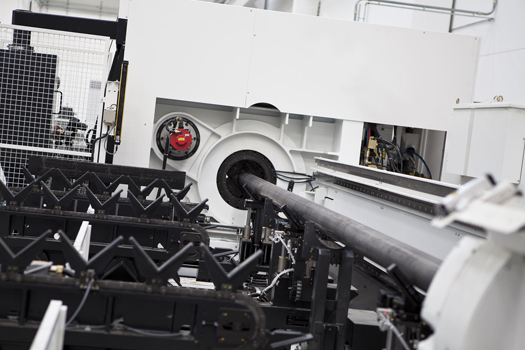

A horizontal press allows the deformation process of the tube and the tapering of the various trunks to different diameters. Making a tapered pole with a high aesthetic impact makes the difference in urban-type installations.