The R&D department can count on a laboratory equipped with the best equipment and machinery with which to perform all the verification tests, guaranteeing and demonstrating the quality of the solutions and verifying the stability of performance over time. All in accordance with the standard requirements.

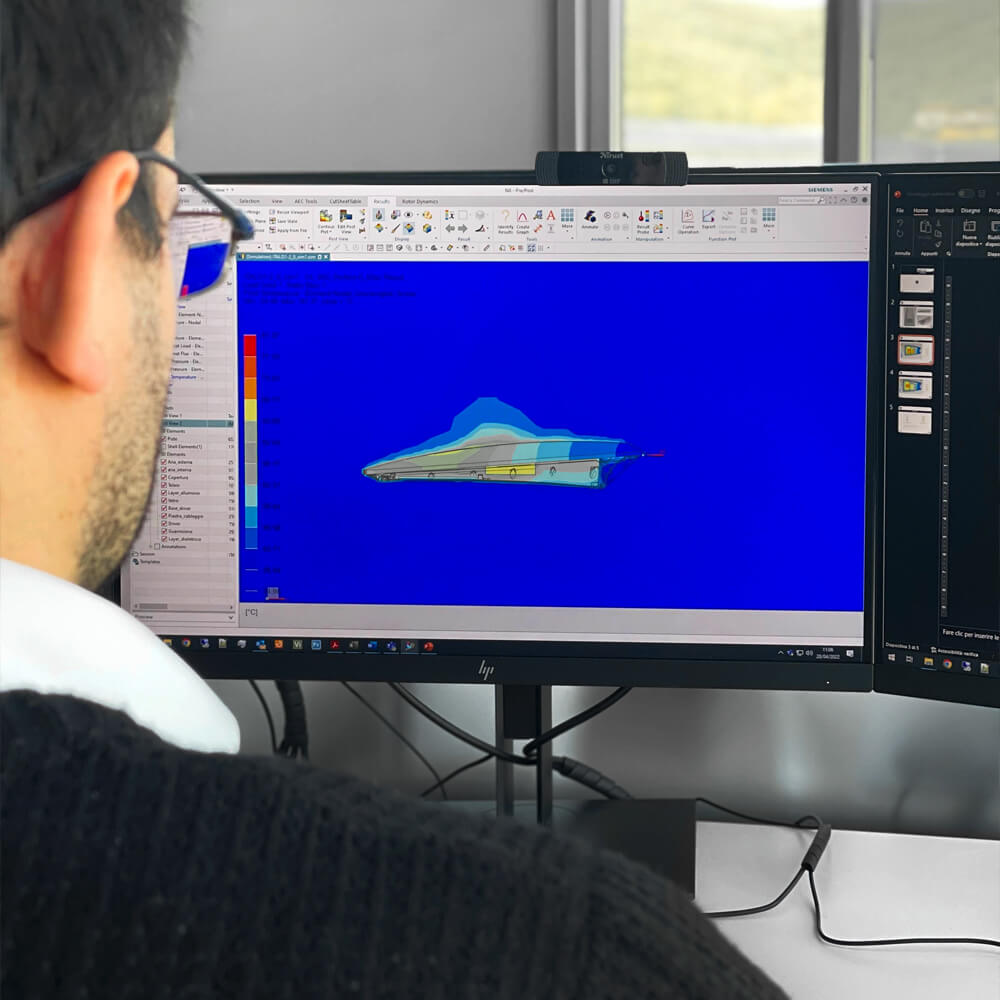

The thermal study is part of the CAD simulation activities and guarantees total reliability of the luminaire in any environment and situation. The CFD and FEM software of the Siemens package is used by AEC technicians to develop the heatsink concept, define the layout of the optical module and ensure the correct functioning of the electrical and electronic components inside the luminaire.

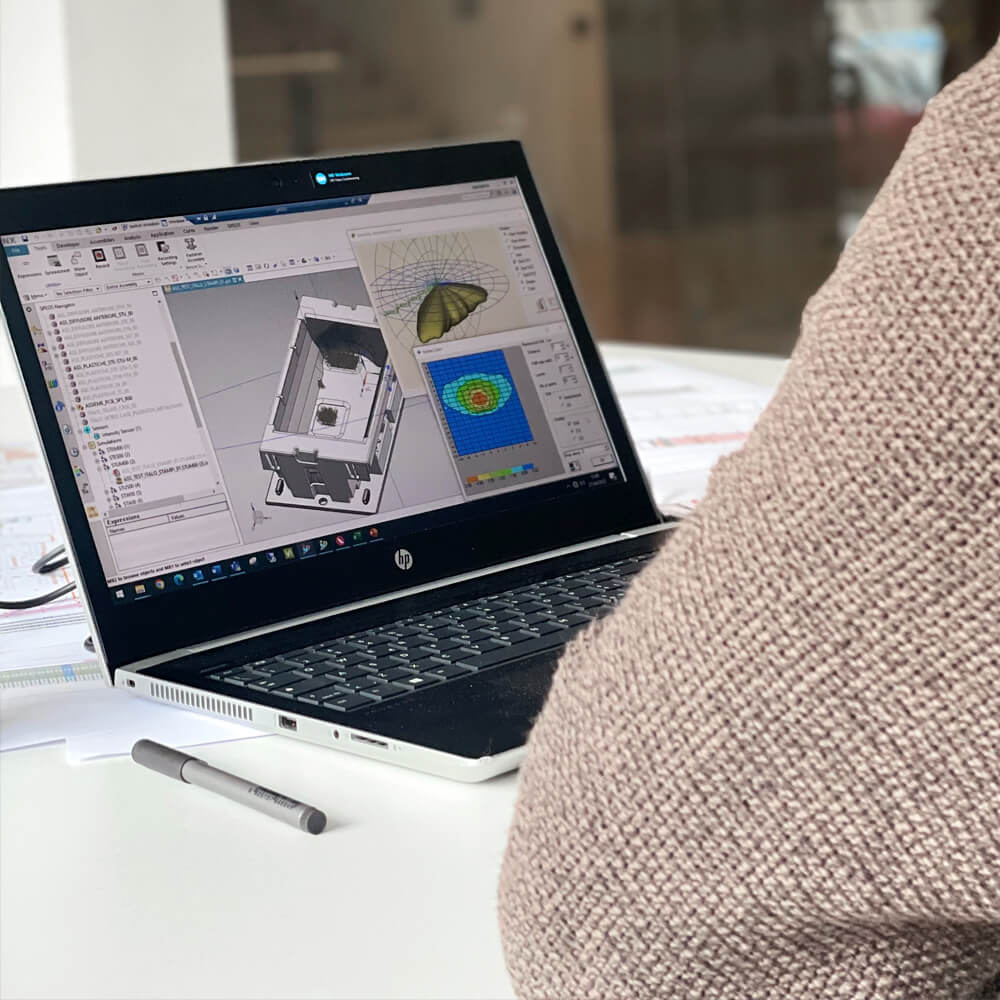

The design process of optical systems within the AEC R&D team is supported by specific simulation software. The software inside allows you to recreate and use all the physical elements that contribute to the emission and management of light. LED sources, lenses, reflectors and glass can be recreated in the smallest detail.

In this phase, the realization of the punch is observed by means of a 5-axis high-speed milling center. This phase is one of the most important as it creates the reflective part of the optic. The processes are carried out with specific hard metal tools, followed by a polishing phase until the surface is mirrored.

In this image, you can appreciate the perfectly polished mold formats mounted inside the shear mold. The technological characteristics of these presses allow to achieve exceptional molding performance and speed, controlling the entire process in an automated way.

The “servo” technology allows you to set the parameters of height, pressure and speed with centesimal adjustments, monitoring the quality of production. The aluminum strip, which is stored in the form of coils, enters from the loading side of the press, runs along the mold for its entire length pushed by the feeder and is printed in the final shape.

Accredia is the authority designated by the Italian government to certify the competence, independence and impartiality of the bodies and laboratories that verify the compliance of goods and services with the standards.

Discover it

ENEC is the official European mark for the certification of electrical products. AEC luminaires are ENEC certified and are subjected to checks carried out by external laboratories and inspectors.

Discover it

Dekra is a European company that deals with testing, inspection and certification. In compliance with the reference standards, AEC laboratories are supervised by DEKRA Testing and Certifications S.r.l.

Discover it

Underwriters Laboratories Inc. is an independent safety certification organization. Underwriters Laboratories develops standards and tests for products, materials, components and tools with a focus on safety.

Discover it