Testing laboratories accredited by Accredia

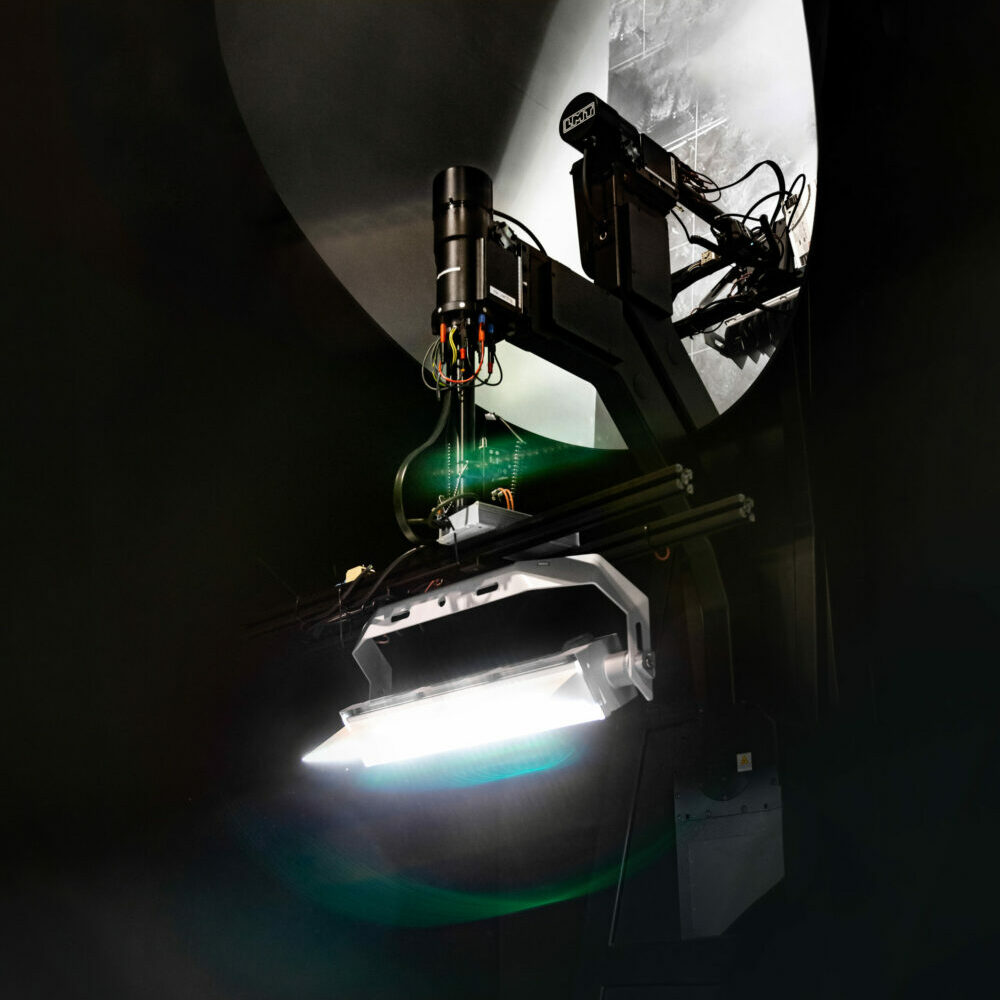

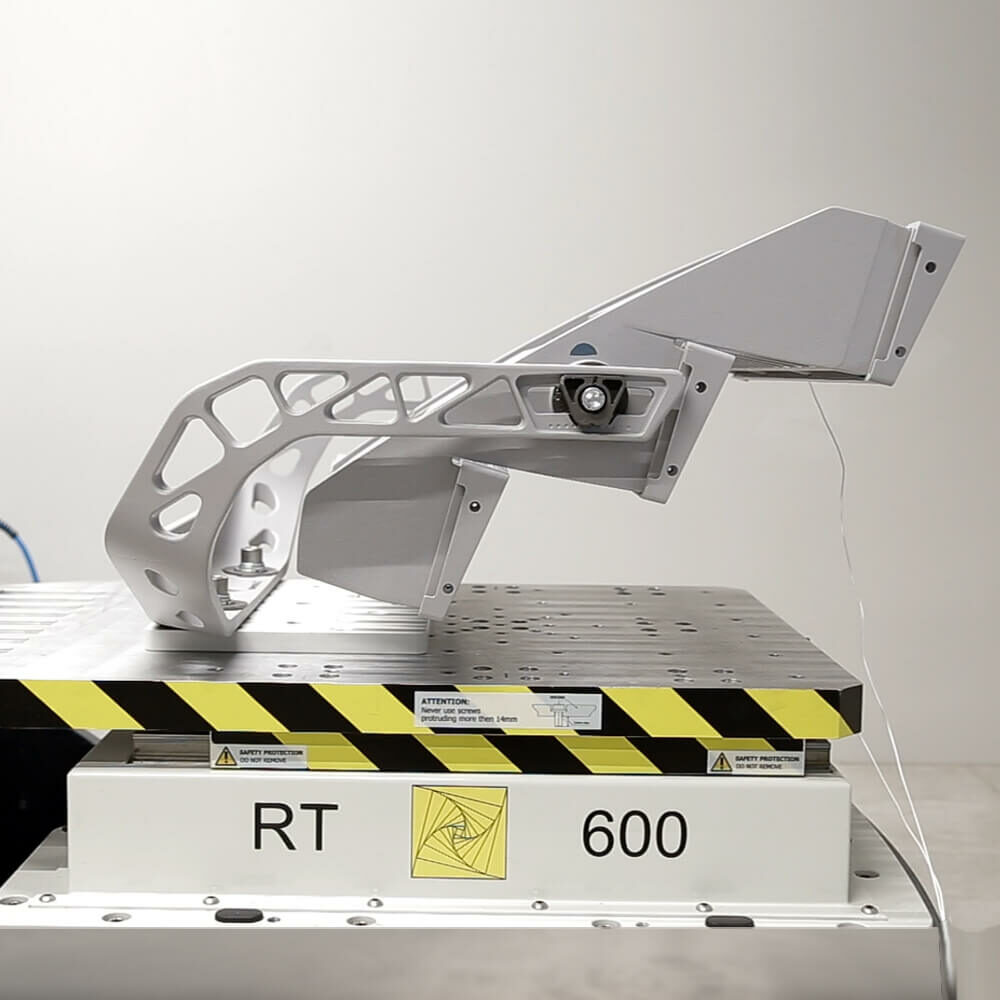

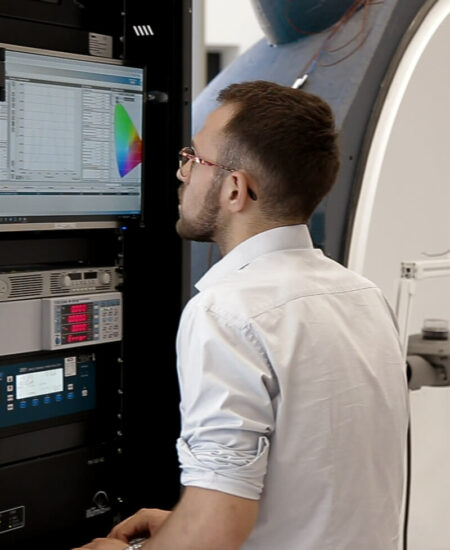

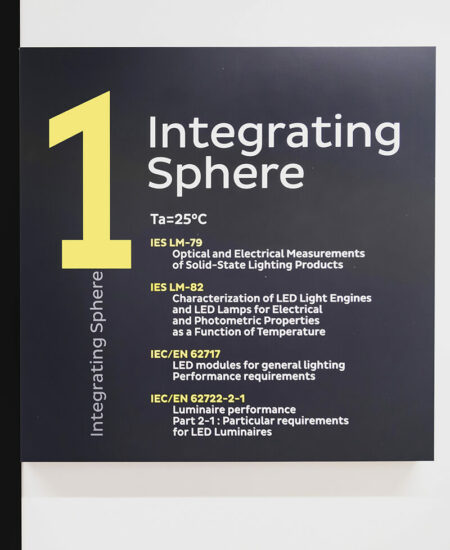

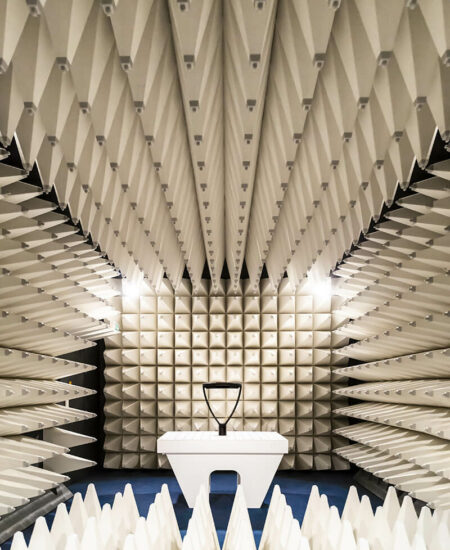

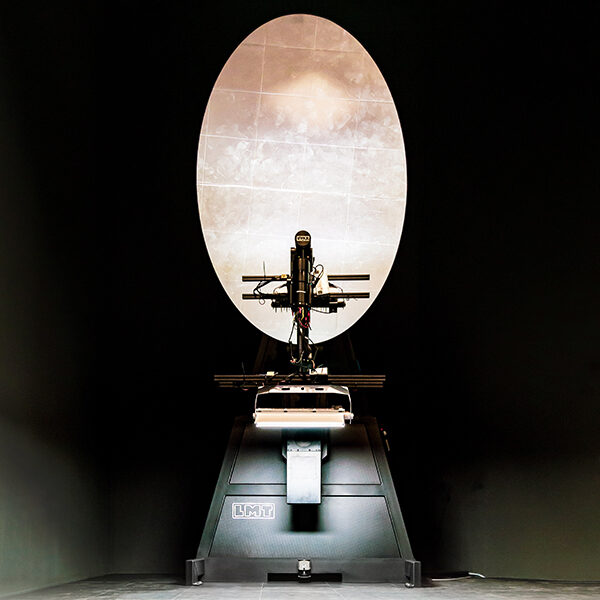

The new AEC laboratories approved by the Ministry of Economic Development

The AEC testing laboratories are accredited by Accredia with No. 1931 L. The updated list of accredited tests can be consulted directly on the website www.accredia.it. The accreditation of the Laboratory involves the verification of the technical competence relating to the accredited tests and of its Management System, in compliance with the UNI CEI EN ISO / IEC 17025 standard. With the accreditation, Accredia ensures the technical competence of the personnel, the adequacy of equipment and equipment and the suitability of the facility.

Discover more